Turnkey 100 TPD (Tons Per Day) palm oil refinery plant is a large-scale industrial project that converts crude palm oil (CPO) into high-quality edible oil, typically through a continuous refining process. In a turnkey model, the provider handles everything from initial design and equipment manufacturing to onsite installation and commissioning.

Crude Palm Oil is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude palm oil produced by palm oil mills should be refined in palm oil refinery plant. Palm oil refinery process mainly includes palm oil degumming, palm oil neutralizing, palm oil bleaching and palm oil deodorization.(Read more about 1-10TPD Palm Oil Refinery Machine >>)

Degumming:

Degumming is to remove impurities such as phospholipids, gum, protein before oil storage and transportation. Gum yielded in the degumming process can be used as raw material for producing lecithin. We provide solutions and equipment for water degumming, dry degumming, special degumming, enzyme degumming and etc.

Neutralizing:

The purpose of neutralizing is to remove free fatty acid, phospholipids, gums or solids in edible oil by using caustic soda. We offer solutions featuring higher oil yield and lower energy consumption.

Bleaching:

Bleaching process removes coloured matters, residual pesticides, metal ions by mixing bleaching earth with edible oil. pre-bleaching process allows for better bleaching effect while using less bleaching earth.

Deodorizing:

Deodorizing, the most critical step in the refining process, effectively removes odorous substances, raises smoke point of oils, improves the stability, color and quality of oils, and removes fatty acids, peroxides, polycyclic aromatic hydrocarbons, residual pesticides, etc. deodorization process retains more active nutrients while producing less harmful substances such as trans fatty acids and trichloropropanol. QIE Group also provides fatty acid two-stage collecting system to improve the economic value.

Dewaxing:

Some kinds of oils contain wax, which affects digestion and flavor and shortens shelf life in winter. Therefore, it is necessary for dewaxing. We have developed a more efficient continuous crystallization technology that has a high crystallization efficiency and excellent dewaxing.

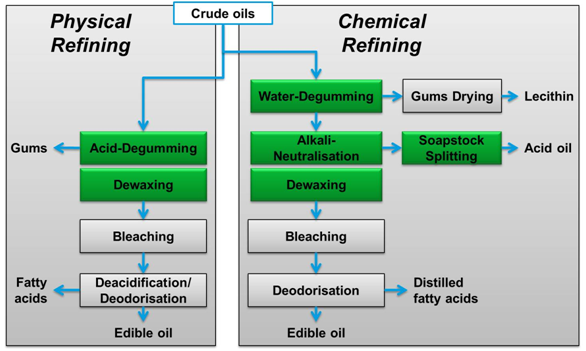

Crude palm oil can be processed by either physical refining (distillative neutralization, steam stripping) or chemical refining (alkaline refining) to produce RBDPO and NBDPO. RBDPO refers to refined, bleached and deodourised palm oil, while NBDPO refiers to neutralised, bleached and deodourised palm oil.(You may also interested in Ultimate Guide to Palm Oil Manufacturing Plant >>)

Physical Refining of Palm Oil

Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, Fuller’s Earth is used to remove colouring matters and adsorb any metal ions. The deacidification and deodorization process is under high temperature and low pressure. By used of live steam, the FFA is stripped of. The steam is then recovered together with the entrained oil is as palm fatty acid distillate. The off-flavors and odours can also be removed from the crude palm oil in the steam distillation process. Before polishing, the refined oil needs to be cooled to 55°C.

Chemical Refining of Palm Oil

In the chemical refining process, the FFA is removed by neutralisation with caustic soda (sodium hydroxide). This chemical reaction produces neutralised CPO and a soap stock. By used of a high-speed separator, the soap stock can be separated from the oil. Then, through earth bleaching, colour pigments and metal ions are removed from the neutralised oil. Then, in deodorization process, odoriferous matters such as ketones and aldehydes are removed by steam distillation under vacuum.

Refining pot: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

Decolor pot: used to remove off pigments, bleaching oils and grease dehydrate.

Deodor pot: used to remove off oils odor, foreign smells (stainless made).

Heattransfer oil stove: supply each device production needing heat energy, temperature reach above 280 ° C.

Steam generator: produce the needing steam for de-odoring and distillation.

Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor

Press filter: filter clay, filter out clear oil.

Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

Engineering & Design: Includes factory layout, process flow design, and equipment selection based on specific oil quality targets.

Full Equipment Suite: Key machines include neutralization pots, bleaching tanks, deodorization towers, heat exchangers, vacuum pumps, and filter presses.

Support Services: Suppliers typically provide technical support, on-site debugging, and operator training to ensure the facility meets production standards.

Logistics & Installation: Handling the shipping of heavy machinery and the complex assembly of refining columns and piping.

QIE Machinery is now one of the largest palm oil production line supplier, with certification ISO9001:2018 and CE. We are expert in manufacturing palm oil press machine and palm oil refinery equipment. If you have any interests in palm oil refinery plant, please contact directly.

What is the final product of the 100TPD palm oil refinery plant?

The primary finished product is refined, bleached, deodorized palm oil (RBD PO) meeting international food grade standards (e.g., Codex Alimentarius, EU/US FDA, or local African/Asian food safety norms). Optional by-products include palm fatty acid distillate (PFAD) and bleaching earth cake (recyclable or for industrial use).

Which refining method is best for 100 TPD capacity?

A Full-Continuous Refining Process is standard for capacities over 30 TPD.

Advantages: Higher automation, 24-hour continuous operation, better refining consistency, and lower labor requirements.

Comparison: Batch refining is best for <10 TPD, while semi-continuous is used for mid-range (10–30 TPD) operations.

What byproducts are produced?

A well-run refinery aims for a “zero waste” model by utilizing byproducts:

Palm Olein & Stearin: Separated via a fractionation plant; olein is used for cooking oil, while stearin is used for solid fats like margarine.

Soap Stock: A byproduct of chemical refining used in soap manufacturing.

Biomass: Palm kernel shells and fibers are often reused as fuel for the plant’s boilers.

What is the processing technology adopted for this plant?

It uses the standard physical refining process (the most cost-effective and widely used technology for palm oil), consisting of four core steps: Degumming → Neutralization (for physical refining, acid degumming is the key) → Bleaching → Deodorization. Chemical refining is available as a customized option for crude palm oil with ultra-high FFA (≥8%).

Does the supplier send technical staff for on-site installation and training?

Yes. The turnkey package includes on-site technical service by experienced engineers (number based on project scale: 2-4 engineers). Services cover:

Foundation guidance and equipment installation supervision;

Piping, electrical wiring, and system debugging;

Hands-on training for operators (equipment operation, parameter adjustment, daily maintenance);

Training for maintenance staff (troubleshooting, spare parts replacement, routine inspection);

A detailed operation and maintenance manual (English/ local language) is provided.