Our palm oil refining equipment unit for small scale production has all the bells and whistles including decreased land usage requirements and investment capital. Due to the small size of the equipment set, it is also easy to install and maintain. There are several types of crude oils you can choose to work with including palm oil (CPO), palm kernel oil (PKO) and other types of vegetable oil such as sunflower oil, fish oil, peanut oil, etc.

Production Capacity: 1-30TPD

Production Capacity: 1-30TPD

Processing Capacity:

0.5-80TPH

Processing Capacity:

1-100TPH

Processing Capacity:

1-60TPH

all machine can be customized according to customers' needs.

This small palm oil refining machine consists of refining tank, decolorizing tank, deodorizing tank and filter, oil pump and electrical control system. It can realize palm oil degumming, deacidifying, drying, decolorizing, and deodorizing.

Meet food processing machinery standards: Made of stainless steel, and polished.

Simple design, beautiful appearance and high customer satisfaction.

Easy operation: Ordinary staff can run the palm oil refinery smoothly after our onsite training.

It can realize the complete process of palm oil refining.

QIE Machinery, as a premier manufacturer of palm oil refining facilities in the industry, is committed to delivering clients refined palm oil plants tailored to their specific needs. We offer a comprehensive suite of services that cover the entire palm oil refining process, encompassing plant design, equipment selection and production, on-site installation and commissioning, operator training, and more. Here, we present the complete steps of our palm oil refining production for your consideration and inspiration.

| Refining process | Removed impurities |

| Filtration | suspended particulate impurities and other mechanical impurities. |

| Degumming | phospholipids, sugar, protein and trace metals |

| Dewaxing | waxy crystals |

| Neutralization | free fatty acids, phospholipids, pigments |

| Decolorization | pigments, oxide, trace metals, waste clay, gum |

| Deodorization | free fatty acids, odorous substances |

| Polishing filtration | residual trace insoluble |

You have the opportunity to carefully select which type refining process you want to specialize in. There are three common types of edible oil refining process: batch oil, semi-continuous oil, and continuous oil. Each type of refining process can determine the exact size and detailing process of the refinery plant.

Batch Oil Refining Process (1~30 ton/day)

This line of an oil refinery is perfect as a mini or small-scale palm oil mill plant. It requires low investment capital and a smaller occupation of land. You are able to refine almost every type of crude edible oil. The primary refinery process includes three stages which are de-gumming, neutralizing, bleaching, and deodorizing. This process eliminates all the impurities which make the oil inedible.

The refining process also includes making the oil palatable and rancid-resistant if and when it is stored for long periods of time. Batch oil refining holds a capacity of 1TPT to 30TPD.

Semi-Continuous Oil Refining Process (10~50 ton/day)

This line is suitable for medium-scale palm oil refining factory which are efficient in accommodating clients requests. You are able to refine different types of crude oils as well as plant and animal oils. It has a capacity of 10TPD to 50TPD.

Continuous Oil Refining Process (over 30 ton/day)

This line is specifically for large-scale palm oil refinery. It operates automatically with the refinement of the oils with the utmost efficacy. lts daily capacity stands at over 30TPD.

Years of development have brought customers from all over the world. Contact us to start customizing a palm oil production line for your business.

Our palm oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the palm oil production equipment and palm oil production lines we manufacture. Whether you need a single palm oil production equipment or a complete palm oil production line, we can customize it for you.

Country : Peru

Production Output : 20TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Philippines

Production Output : 40TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Mexico

Production Output : 30TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Cote d’Ivoire

Production Output : 160TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Indonesia

Production Output : 120TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Thailand

Production Output : 100TPD

Raw Materials : Palm Fruit, Palm Kernel.

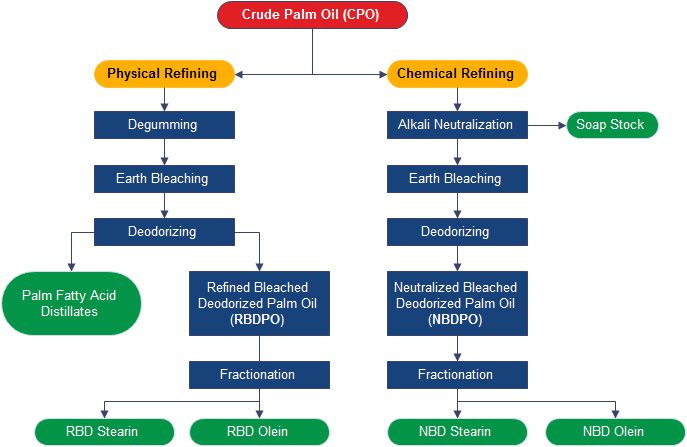

It's a piece of industrial equipment designed to process crude palm oil (CPO) into refined, bleached, and deodorized (RBD) oil, which is suitable for various food and industrial applications.

Components vary by type but generally include a degumming machine for removing impurities, a bleaching machine for decolorization, a deodorizing machine to remove odors, and a dewaxing/winterization system for removing waxes.

1) Our palm oil refining machine is suitable for various vegetable oils and animal oils and fats, including coconut oil, palm oil, soybean oil, peanut oil, sunflower oil, cottonseed oil, chicken fats, fish fats, and more.

2) We can provide the custom-made stainless steel palm oil refining machine, but the cost is usually higher than the normal palm oil refining machines that are made of carbon steel.

The palm oil extraction process usually includes the following steps: sterilizer, thresher, digester&presser, crude palm oil clarification, red palm oil drying and so on.

1) Steps 1—— sterilization: After collecting, by hot water or steam to make the fresh palm fruit bunches(FFB) be soft. Sterilization process is good for the behind processing, and reducing the damage of palm kernel.

2) Steps 2——threshing: Separating the palm fruits from FFB, and get the palm fruits to press the crude palm oil.

3) Steps 3—— pressing: Using the digesting machine to break the palm fruits into pulps, and then using the palm oil pressing machine to press the crude palm oil.

4) Steps 4—— clarification: After oil pressing, there are some fibers and other impurities in the crude palm oil, after clarification, you will get the cleaning CPO.

5) Steps 5 —— Final oil drying: Using the drying machine to remove the water of the palm oil, it will make the palm oil more stable and extend its storage time.

In order to remove impurities and harmful substances in crude palm oil and improve the oil quality and market competitiveness, more and more investors choose to purchase palm oil refining machine to refine the obtained crude palm oil. In fact, the function of palm oil refining machine is not limited to this, it can achieve multiple purposes.

The palm oil refining machine can not only refine crude palm oil and palm kernel oil, but also refine the crude oil pressed by conventional oil seeds such as soybean, rapeseed, peanut, sunflower seed, sesame, castor bean, corn germ, etc.

In the main producing countries such as Malaysia, Indonesia, Africa or the Southern American states in particular, palm oil is in demand not only as a raw material in the production of foods, cosmetics or cleaning agents, but also as an edible oil. In order to render the palm oil obtained edible, it has to be refined to remove by-products. Pre-treating the crude oil with acid and hot water saves bleaching earth in the subsequent physical deacidification process and thus reduces overall costs.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of palm oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for palm oil and palm kernel oil production. Customize the palm oil processing equipment capacity according the different customers requirements.