Palm oil is a versatile and highly sought-after edible oil due to its high levels of saturated and unsaturated fatty acids, making it a key ingredient in many food and cosmetic products. Palm oil production is a major industry in tropical regions, where it is used both as a cooking oil and a raw material for the production of soap, margarine and other products. Palm oil is also used in a variety of industrial applications, including biofuels, lubricants and waxes. As a result, it is a valuable commodity with an increasing global demand.

Nigeria remains a significant global producer of palm oil, although its historical dominance has waned, leading to a position as a net importer despite its large-scale production. The sector is characterized by widespread smallholder farming and reliance on manual processing, with a growing domestic market and potential for industrial uses like biofuels. Key challenges include the decline of large-scale plantations and the need for sustainable agricultural practices to revive its former glory in the global palm oil market.

Equipment for Producing RBD Palm Oil: Refined Bleached Deodorized Palm Oil

You can get palm oil olein and palm oil stearin after crystallization at controlled temperatures in palm oil fractionation plant.

This small scale palm oil refining plant in Nigeria consists of refining tank, decolorizing tank, deodorizing tank and filter, oil pump and electrical control system. It can realize palm oil degumming, deacidifying, drying, decolorizing, and deodorizing.

Palm Oil refining: crude oil – degumming&dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Brief description of 4 palm oil refining steps are as follows:

Palm Oil Refinery Plant can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

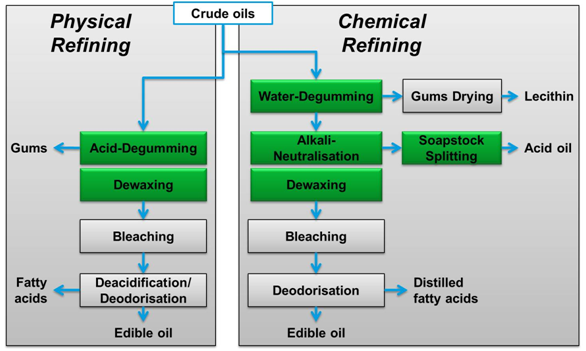

There are two refining methods for the vegetable oil refining in the edible oil refinery plant. They are physical refining and chemical refining. Physical refining means removing gum in oil during process of degumming in special method and removing FFA in process of deodorizing by steam. Chemical refining, however, means removing FFA in a chemical way ( Acid-base neutralization). Gum and soap foot produced is separated by centrifuges.(Related post: Palm Oil Mil Plant Setup Costs in Nigeria >>)

Vegetable oil refining – Chemical Refining

1.The finished edible oil is consistent and stable.

2.Excellent adaptability and less requirement to oil quality.

3.Less bleaching earth is added into compared with physical refining.

Vegetable oil refining – Physical Refining

1.High oil refining rate, less oil loss.

2.No waste water discharged.

3.Especially suitable for oils of high acid value, and low gum content.

4.More FFA distilled out.

Refined palm oil should go through fractionation process to separate solid phases (Stearine) and liquid phases (Olein). It is achieved by thermo-mechanical means. Fractionation can greatly maximize the value of products. Our fractionation project adopts dy fractionation process. We have posted the advantages and disadvantages of 3 common fractionation process of palm oil production which showed why dry fractionation is the best choice.

The typical fractionation process of palm oil mill is pre-heating, cooling, crystallization, and filtering.

Palm oil fractionation plant in Nigeria has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Nigeria, Africa’s leading palm oil producer, faces enormous challenges: domestic demand continues to soar, yet over 70% of the palm oil is imported! Domestic production cannot meet the shortfall, traditional palm oil processing methods are inefficient and offer inconsistent quality, and many plantations remain untapped. How can this situation be reversed?

Efficient Pretreatment Unleashes the Potential of Oil Palm Fruit

Traditional palm oil methods in Nigeria result in high fresh fruit bunch (FFB) losses and low oil yields. QIE’s continuous sterilizing tanks and high-efficiency crushers rapidly inactivate enzyme activity and thoroughly crush the fruit, paving the way for subsequent oil extraction and significantly improving oil yields.

Core Oil Extraction Technology: A Win-Win for Quality and Efficiency

Palm Oil Screw Press: QIE Machinery offers flexible configurations for processing plants of varying sizes in Nigeria. Its powerful compression ensures low residual oil content in the dry cake and more thorough oil extraction.

Centrifugal Separation System: This replaces traditional sedimentation methods, instantly separating crude oil, water, and residue phases through high-speed centrifugation. This delivers high throughput, high efficiency, and a purer oil product, significantly reducing the burden of subsequent refining.