Oil palm belongs to palmaceous plant; its main producing area distributes tropic area between the south latitude 5~10°and the north latitude 5~10°near the equator; It is an important tropic oil seed plant. The palm oil content is very high: common fresh fruit :46~50% , palm kernel :50~55%.

Oil palm begins to bear fruits about two years and a half after being transplanted. Firstly, the output is very low, 8~15years is blooming time and output reach maximum; it gradually aging when it grows over 20 years; its growth period is 25~30years. Per-hectare land should plant about 140-palm tree in general, annual output is about 20T fresh fruit bunches; after being processed, about percentage 20 is crude palm oil and percentage 20 is kernel.

The main production area of palm oil is: Indonesia, Nigeria, Thailand, Columbia, Cote d’Ivoire, Papua New Guinea, Honduras, Ecuador, Brazil etc.

Nigeria was the largest palm oil market between 1950s to 1960s. At that time, its palm oil production had exceeded its domestic consumption, and the exceeded part was exported to the world’s market. However, the development of palm oil production was adversely changed after that.

A complete palm oil mill plant is a multi-stage process involving specialized equipment and techniques to convert fresh palm fruit into refined edible palm oil. We provide turnkey palm oil processing plant solutions from oil mill plant layout design to oil machinery manufacturing, onsite debugging, and installation. The palm oil processing plant capacities range from 3tph to 120tph.

Our unique patented palm oil equipment and techniques are highly efficient in handling the specific properties of palm fruits and achieving maximum oil yield and quality. We have the best solutions for you in each stage, from palm sterilization and threshing to palm oil extraction and refining. We aim to offer a tailor-made palm oil production plant for every customer and guide you in mastering palm oil extracting and refining technology. (Related Posts: Palm Oil Refinery and Fractionation Plant in Nigeria>>)

Raw material reception

As for the first step of palm oil mill process,collecting the FFB and convey by trucks, then pour the fluster into the discharge door after weighed.

Sterilization

FFB are airtight sterilized in sterilizer of palm oil mill process, the purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

Threshing

The purpose of threshing in the palm oil mill process is to separate the palm fruit from the FFB. The drum type thresher is the usual machine to separate the fruit.

Digesting and pressing

The purpose of digesting in the palm oil mill process is to separate the pulp and nut and crush the palm pulp. Then it is sent to continuous screw press. After pressing of palm oil mill process, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

Oil clarification

As for the oil clarification of palm oil mill process,oil is clarified by the vibrate screen.

Kernel recovery

As for the last step of palm oil mill process, The separated fiber material is sent to the boiler room as fuel; the separated kernel is transported to kernel warehouse by pneumatic conveying system for temporary storage.

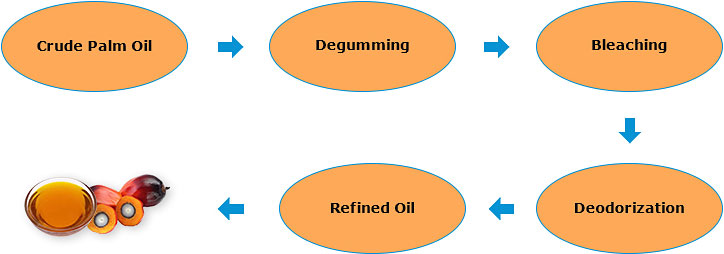

Palm Oil Degumming and Deacidification Section:

Palm oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step palm oil refinery process.

Palm Oil Bleaching Section:

Palm oil bleaching section is mainly used to remove oil pigment, residual soap and metal ions during palm oil milling process.

Palm Oil Deodorization Section:

Palm oil deodorization section composes of part of crude palm oil mill processing equipment. It plays important part in improving oil quality after crude palm oil process.

How much it will cost to set up a palm oil processing mill in Nigeria? Generally, the total cost of establishing a palm oil processing mill plant will be decided by many factors, including: the palm oil processing capacity, the quality and quantity of palm oil processing machines and equipment, the palm oil suppliers and more. Therefore, the exact cost of setting a palm oil processing mill plant in Nigeria would vary from the different requirements and specific situations. The following data is just for reference:

A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around.

The exact cost of starting a palm oil milling business in Nigeria depends on the capacity requirments, process design and equipment configuration.

QIE Machinery, the top-rated palm oil mill plant supplier, has gained rich experience to provide the palm oil processing machines in Nigeria. We boasts professional design and development team to customize the advanced palm oil processing machines and techniques for our Nigeria customers. Believe it or not, there, you will enjoy the first-class service and premium quality machines.