If you are planning to setting up a palm oil Processing pant in indonesia, you must have deep understanding of the local palm oil market, project construction cost, production cost and return. QIE Machinery has the core business in delivering the technology, engineering and services over the world within the field of Palm Oil Mill Machinery.

Indonesia is the world’s leading producer of palm oil, with production concentrated on the islands of Sumatra and Kalimantan. The industry is a significant part of Indonesia’s economy, contributing to its GDP and employing millions of people. However, its expansion has led to widespread deforestation, biodiversity loss, and social conflicts with local communities.

A palm oil processing plant is a facility designed to produce crude palm oil (CPO) and palm kernel oil (PKO) from the oil palm tree’s (Elaeis guineensis) fruit. The processes involve sterilization, threshing, pressing, clarification, and separation. Some of the primary equipment includes sterilizers, digesters, screw presses, and clarifiers. Due to the level of production and environmental concern, sustainable processes, waste management systems, and energy-efficient technologies are essential. Palm oil manufacturing plant serve a wide variety of industries, such as food and beverage, cosmetics, pharmaceuticals, and biofuels.

Palm Oil Processing Plant is very different from other common oil seeds. It mainly includes 9 sections:

1. Raw materials storage section of palm oil production:Fresh palm fruit bunch must be first measurement recorded by the pound into the plant, then unloaded to loaded fruit slopes and stored.

2. Sterilizing section of palm oil production: fresh palm fruit bunch are airtight sterilized in sterilizer. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase; easy threshing machinery; pretreatment peel, prepared for the follow-up processing; pre-conditioning stone, reducing the damage kernel.

3. Threshing section of palm oil production: The purpose of threshing is to separate oil palm fruit from the fruit bunch through strong vibration.

4. Palm oil pressing section of palm oil production: Before pressed, oil palm fruit first be carried out cooking, sterilized fruit must be re-heated to make the pulp soft and damage pulp cell structure. Then enter into continuous screw press.

5. Palm oil clarification section of palm oil production: Machine-pressed crude oil first diluted with water washing, the fiber material removed from the oil through settlement and filtration, and then carry out continuous settlement.

6. Finished crude palm oil is stored in storage tanks.

7. Fiber separation section of palm oil production: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating.

8.Kernel recovery section of palm oil production: After separation, shell is sent to the warehouse for temporary storage, as boiler room fuel when necessary; Dried kernel is sent to kernel storage warehouse for storing.

9.Sewage treatment section of palm oil production: Pool sewage treatment system is the most used and effective treatment.

The crude palm oil refining plant process consists of following section:

1.Neutralizing Section

First stage of crude palm oil refining process is to remove Free Fatty Acids (F.F.A.) with caustic soda treatment called Neutralizing Process, thereafter further processed in the bleaching section under vacuum & treated with bleaching earth & activated carbon for removing colour. Finally it will be deodorized under high vacuum and high temperature to remove the odour from the oil.

2.Bleaching Section

The Oil received from previous stages contains traces of soap, iron and few ppm of Phospholipids and Carotenes. These contents are undesirable and required to be removed in Bleaching Operation of crude palm oil refining process, Doing’s Steam Agitated Bleacher comprises of an acid treatment, a separate Oil and Earth Mixing Device with Mechanical Mixer (this arrangement ensures no carryover of bleaching earth into vacuum system), main bleaching vessel and Hermetic Filters.

3.Deodorizing Section.

Physical Refining process is used to remove FFA (Free Fatty Acid), using Steam Distillation method at high temperature and under high vacuum and it is followed by Deodorization and an extra technical facility is added before deodorisation for removal of free fatty acid.

Deodorization process is used to remove unacceptable odour by Steam Distillation, the Odoriferous Compound are strip off with the help of live injected steam into heated oil under high vacuum.

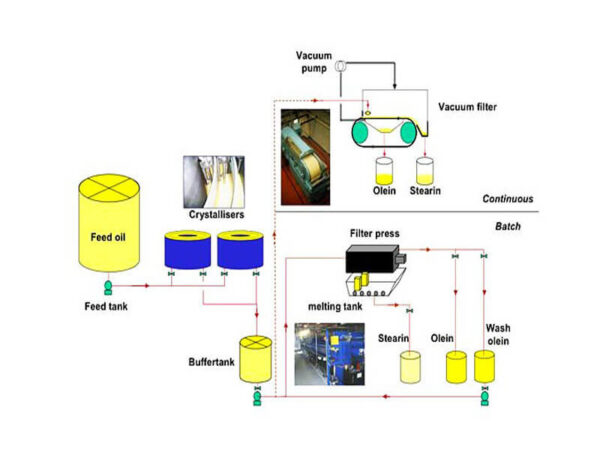

Fractionation is the special treatment for palm oil. According to customers’ requirements, we can customize the Fractionation process to Separate solid and liquid parts of the oil, allowing the production of palm olein (liquid) and palm stearin (solid). A palm oil fractionation plant is a good choice if you want to increase the added value of palm oil products and the economic benefit of your enterprise. Our palm oil fractionation plant adopts advanced crystallization equipment, filtration equipment, and accurate temperature auto-control software to separate palm olein and palm stearin which can get different melting-point fractionation products, including 18℃, 24℃, 32℃, etc.

Lowering the palm oil temperature to about 24 ℃ for a definite time will crystallize and separate the ingredients with a high melting point. After secondary filtration, the palm oil can be fractionated into three products with different melting points, which are palm stearin (melting point>40℃), palm palmitin (melting point about 30℃), and liquid palm oil (melting point <20℃). The quality of liquid palm oil can reach the standard of high-level edible oil.(Read More: Palm Oil Refinery Plant Setup Costs in Nigeria>>)

Palm Oil Fractionation Technical Process

The fractionation methods of palm oil are composed of dry fractionation, solvent fractionation, and surfactant fractionation.

Dry fractionation

Palm oil→heating→cooling and crystallizing→filtering→palmitin, stearin

Solvent fractionation

Palm oil→solvent diluting→cooling and crystallizing→separating→solvent evaporating→palmitin, stearin.

Surfactantfractionation

Palm oil→cooling and crystallizing→water soluble surfactant solution adding→stearic crystal wetting→centrifugal separating→washing→drying→palmitin, stearin.

Indonesia is the world’s largest producer of palm oil —a staple agricultural commodity found in about half of all packaged products sold in supermarkets. The country produces more than 30 million tons of palm oil per year, generating 4.5% of its GDP and giving employment to 3 million people. With steady double-digit growth rates, the sector has become vital to the country’s economy. However, unsustainable palm oil production is also contributing to rapid tropical forest destruction and climate change.

The challenge now is maximising the development and economic benefits of this pivotal national commodity sector, all the while minimising its adverse social and environmental effects.

There are three key factors to achieve sector sustainability and ensure a promising future for Indonesian palm oil:

– Boosting farmers’ competitiveness by exposing them to good agricultural practices.

– Address gaps in policies.

– Applying innovative approaches to financing.

– Building effective collaboration between government, civil society, and private sector.