Palm oil refinery machine is a specialized industrial system used to transform crude palm oil (CPO) into high-quality, edible RBD palm oil (Refined, Bleached, and Deodorized) by removing impurities such as free fatty acids, pigments, and odors.

Choosing the right palm oil refinery machine is critical for ensuring high-quality refined palm oil, efficient production, cost-effectiveness, and compliance with local food safety standards—whether for a small-scale workshop or a large industrial palm oil processing plant. The selection process needs to be based on production scale, refining method, refined oil quality requirements, budget, and local industrial conditions .

This is the most important factor.

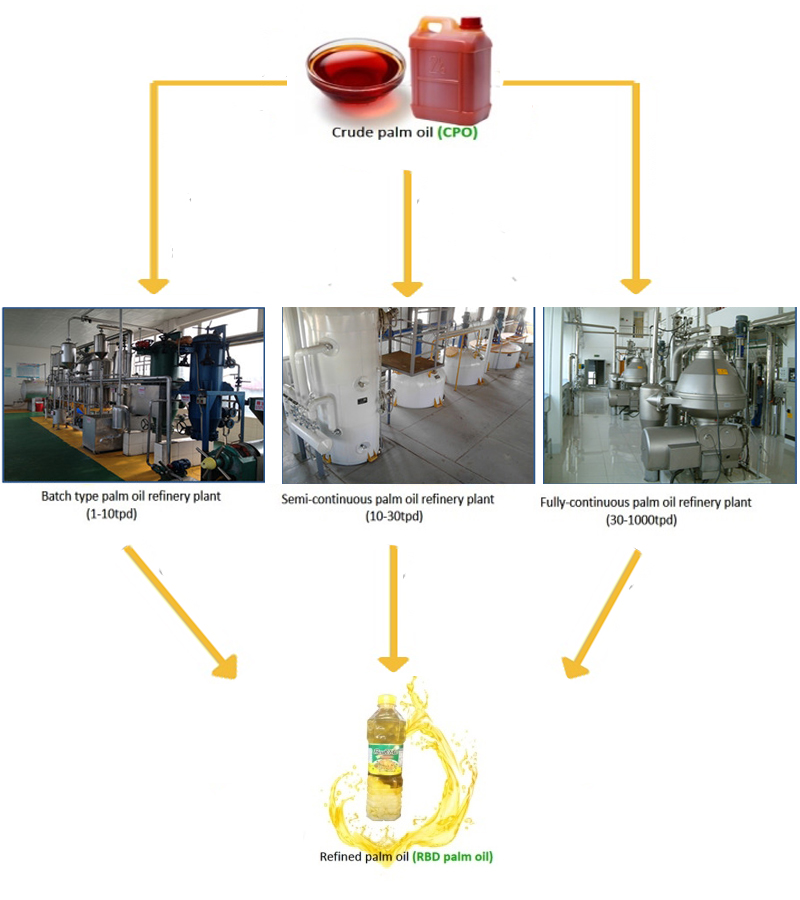

Batch Type (1–10 TPD): Ideal for small to medium-sized operations with lower initial investment and flexibility to process different types of oils. It has higher labor intensity and slightly lower energy efficiency.

Semi-Continuous (10–30 TPD): A middle ground, where some processes (like deodorization) are continuous while others are batched, balancing efficiency and cost.

Continuous Type (30-1000 TPD): Suitable for large industrial operations with high automation, ensuring consistent, high-quality output and better energy utilization, but requiring a significant investment.(Read more about Turnkey 100TPD Palm Oil Refinery Plant>>)

The premier method for large-scale industrial palm oil production line (e.g., Malaysia, Indonesia)—used for CPO with low FFA (<5%) (from well-managed palm plantations with immediate fruit processing). It is the gold standard for high-grade RBD palm oil, export, and specialized food applications (baking, frying, confectionery).

Core Principle

Removes FFA, moisture, and volatile impurities via steam stripping under extreme high temperature (240–260℃) and high vacuum (≤3 mbar). No alkaline chemicals are added—FFA and other volatiles are vaporized and stripped by low-pressure steam, then condensed and removed as a fatty acid distillate (FAD) (a high-value byproduct).

Advantages for palm Oil

High oil yield: Only 0.5–2% oil loss (far less than chemical refining)—critical for large-scale production (saves millions in raw material costs annually).

Superior oil quality: RBD palm oil has higher smoke point (≥230℃), better oxidation stability, and lighter color; ideal for export, baking, frying, and baby food.

Environmentally friendly: No waste water (no water washing) and minimal solid waste (only spent clay); FAD is a high-value byproduct (sold for biodiesel, vitamins, or fatty acid production).

Lower operating costs: No chemicals (NaOH/phosphoric acid) or soft water; less energy consumption overall (fewer steps, no waste treatment).

Continuous production: Adaptable to 50+ TPD (up to 1,000+ TPD) industrial scale; fully automatic PLC control reduces labor costs.

The most widely used method for small/medium-scale palm oil plants (e.g., Nigeria, Ghana, Cameroon)—especially in regions where raw CPO has high FFA (>5%) (a result of poor post-harvest handling of palm fruits, e.g., delayed processing, improper storage).

Core Principle

Neutralize free fatty acids in CPO with a dilute alkaline solution (e.g., 8–12% NaOH, caustic soda) to form soap stock (a fatty acid salt), which is then separated, washed, and removed. Subsequent steps (bleaching, deodorization) polish the oil for edible use.

Advantages for Palm Oil

Ideal for high FFA CPO: The only cost-effective method for CPO with FFA >5% (common in low-income palm-producing regions).

Low initial investment: Compact, simple equipment; no need for high-performance vacuum/ high-temperature systems.

Easy operation & low labor skill: Semi-automatic control; no need for trained chemical/mechanical technicians (critical for regions with limited technical talent).

Flexible scale: Adaptable to 1–50 TPD (tons per day) production (the dominant scale for African palm oil plants).

Byproduct value: Soap stock can be sold to soap/fatty acid manufacturers for additional revenue.

The grade of refined palm oil (RBD Palm Oil) directly determines the refining process and equipment configuration—different markets (local consumption, export, food processing) have distinct quality standards (e.g., Codex Alimentarius, local national food safety standards):

Edible grade (basic): For daily cooking; requires standard refining (deacidification, decolorization, deodorization) | Meet basic FFA ≤0.1%, moisture ≤0.1%, no peculiar smell.

High-grade edible oil: For baking, fried food, or export; add dewaxing/deodorization optimization units | Control carotene content (palm oil’s red color), improve oxidation stability.

Industrial grade: For biodiesel, soap, cosmetics; simplify partial refining processes (e.g., skip high-precision decolorization) | Reduce equipment investment costs.

Palm oil refinery machine costs vary greatly by scale, process, and configuration—avoid blind pursuit of low prices or over-configuration. A reasonable budget allocation should follow:

Cost Composition of Refinery Equipment

Main equipment: 60–70% of the total budget (core modular units: deacidification, deodorization, decolorization).

Auxiliary equipment: 15–20% (boiler, vacuum pump, storage tank, control system).

Installation & commissioning: 5–10% (on-site construction, pipeline connection, debugging).

Spare parts & after-sales: 5% (initial spare parts, maintenance tools).

Cost-Benefit Principle

Small scale (1–10 TPD): Prioritize cost-effectiveness; choose semi-automatic chemical refining equipment (total investment is lower, quick return on investment).

Medium/large scale (10+ TPD): Consider long-term operation cost; physical refining has higher initial investment but lower operating cost (no waste treatment, high oil yield) and better oil quality (higher market price).

Avoid ultra-low-priced equipment: Inferior materials (e.g., carbon steel) or incomplete configuration will lead to high oil loss, frequent maintenance, and even unqualified oil—resulting in greater long-term losses.

Palm oil refinery production generates waste (e.g., soap stock, waste water in chemical refining, waste decolorant) —non-compliance with environmental standards will lead to plant shutdown or fines.

Chemical refining: Choose equipment with a soap stock separation and waste water treatment system (simple coagulation-sedimentation tank for small scale) to meet local sewage discharge standards.

Physical refining: No waste water, only solid waste (spent decolorant)—can be recycled as fuel or fertilizer, low environmental pressure.

Safety standards: Equipment must have overtemperature, overpressure, and vacuum protection devices (to avoid fire or explosion in high-temperature operation); electrical equipment is explosion-proof (for flammable oil vapor).

QIE is industry leading manufacturer in palm oil refinery plant. We provide full set of palm oil refining machines with factory prices. We also supply turnkey projects for pko mill plant and palm oil refinery plant. If there are any needs, please contact us for more details and latest price!