A small scale palm oil mill plant is a compact, cost-effective, and easy-to-operate set of equipment designed to convert fresh palm fruit bunches (FFB) into high-quality crude palm oil (CPO), and optionally refined palm oil. It is tailored for small plantations, rural cooperatives, and local entrepreneurs, especially suitable for regions with abundant palm resources and limited industrial infrastructure, such as Africa, Southeast Asia, and Latin America.

The standard capacity of small scale palm oil processing plant is 1–5 tons per hour (TPH) of FFB, with 1–3TPH being the most popular for village-level and small cooperative use. The equipment can be modularly configured to match local raw material supply and market demand, and supports flexible expansion.

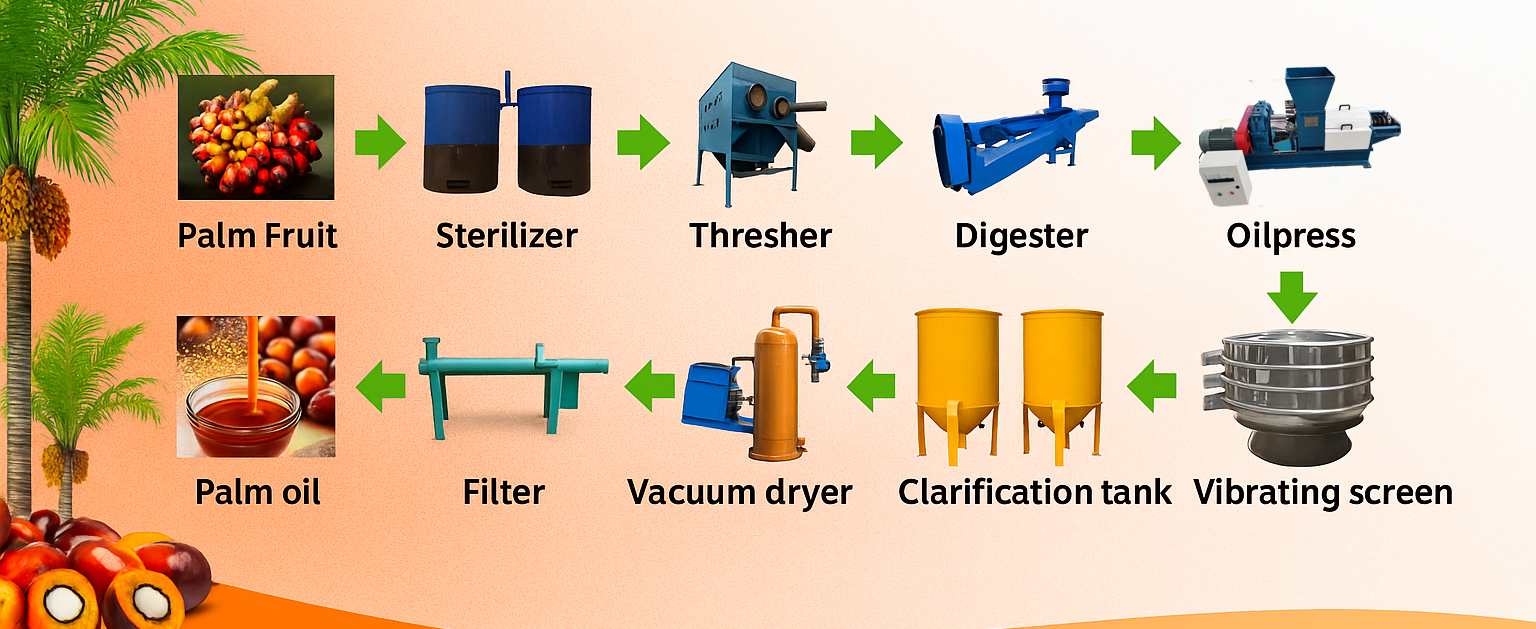

A standard small-scale production line involves several automated or semi-automated steps to extract crude palm oil (CPO):

Reception & Sterilization: Fresh Fruit Bunches (FFB) are heated with steam to deactivate enzymes and loosen fruits.

Threshing: A drum-type thresher separates the fruit from the bunches.

Digestion & Pressing: Fruits are crushed (digested) and then fed into a Screw Oil Press to extract crude oil.

Clarification: The crude oil is purified using a Clarification Tank or filter press to remove water and impurities.

Refining (Optional): Small-scale Palm Oil Refinery Plants (typically starting at $2,500) can further process CPO into high-quality cooking oil.

Sterilizer/Cooking Tank: Uses high-temperature steam or boiling water to soften the fruit and halt the enzymatic activity that increases free fatty acid (FFA) content, ensuring better oil quality. In smaller operations, a vertical sterilizer is often used.

Thresher: A rotating drum machine, like the Palm Fruit Thresher Machine, that mechanically separates individual palm fruits from the large, heavy bunches after sterilization.

Digester: This machine crushes and mashes the softened fruit pulp into a mash. The process breaks down the oil cells, which makes oil extraction more efficient and reduces the workload on the press.

Screw Press: The primary oil extraction machine, such as the Small Palm Fruit Oil Press (often dual-purpose for both motor and diesel engine power). Options include single or double-screw designs, with capacities ranging from 1tons/h to 5 tons/h, known for their high oil yield efficiency.

Vibrating Screen: Used to remove large and light debris from the crude oil immediately after pressing.

Clarification Tank: A settling tank where oil, water, and heavier impurities (like silt) naturally separate by gravity.

Plate and Frame Filter: An important filter that uses a filter cloth system to remove fine impurities from the oil, resulting in cleaner crude palm oil with a longer shelf life.

Vacuum Drying System: Removes any residual water from the crude oil, which is essential for proper storage and preventing deterioration.

Setting up a palm oil mill plant with a capacity of 1–5 tons per hour (TPH) represents a significant jump from micro-scale operations, requiring more automation and high-grade industrial equipment.

Equipment & Installation Costs

For a 1–5 TPH palm oil mill, you typically move away from stand-alone machines to a complete palm oil production line.

Machinery Cost: A complete processing line in this capacity range typically costs between $100,000 and $260,000.

Key Equipment Included: This budget covers an industrial Sterilizer, Drum Thresher, Digester, and Double Screw Oil Press, plus clarifying and filtering systems.

Installation: Professional installation and commissioning often add 10%–15% to the machinery cost

Civil Works & Infrastructure

Building a facility to house a 1–5 TPH line requires substantial industrial space. Plant Construction: A standard 1,000 \(m^{2}\) factory building costs between $123,000 and $197,000.Infrastructure: Providing essential utilities like high-capacity water access, stable industrial electricity, and road leveling typically costs $25,000 to $50,000.Land: Leasing or buying 5 hectares of land for operations can add roughly $6,000 to $12,000 in initial rent or purchase costs.

Estimated Total Project Budget (1–5 TPH)

Summing up the machinery, construction, and infrastructure, the total initial investment (excluding raw material capital) often ranges from $240,000 to over $400,000.

Cost Variation Factors

Automation Level: Semi-automated lines are cheaper; fully automated systems with PLC controls cost 30%–50% more.

Refining Capacity: Adding a mini-refinery (1 TPD) to produce edible oil costs an extra $20,000–$40,000.

How much land is required for a 1–5 TPH palm oil mill?

For this capacity, you generally need 1.5 to 3 hectares. This includes space for the main factory building (approx. 1,000㎡, a fruit reception area (loading ramp), waste treatment ponds, and storage tanks for Crude Palm Oil (CPO).

What is the “Oil Extraction Rate” (OER) I should expect?

A well-maintained 1–5 TPH mill using industrial double screw presses should achieve an OER of 19% to 23%. This means for every 10 tons of Fresh Fruit Bunches (FFB), you should get roughly 2 tons of oil.

How many workers are needed for a 5 TPH palm oil mill line?

A semi-automated 5 TPH line typically requires 15–25 workers per shift. This includes roles for fruit loading, boiler operation, machine monitoring, and quality control.

Should I include a Palm Kernel Recovery plant?

Yes. Adding a kernel recovery line (nut crackers and separators) adds about 15–20% to the equipment cost but provides a secondary revenue stream by selling kernels or palm kernel oil (PKO).

How to train staff for operating a small palm oil mill?

Hire technicians with basic mechanical or agricultural processing experience

Arrange equipment supplier-provided training (most suppliers offer on-site training for machine operation and maintenance)

Train staff on quality control, safety protocols, and waste management practices

Refer to industry guidelines or local agricultural extension services for additional training resources

How to market and sell the finished crude palm oil?

Target local buyers: Local cooking oil refineries, food processing companies, or wholesale traders

Explore regional markets: Supply to nearby cities or border markets (ensure compliance with cross-border trade regulations if applicable)

Establish long-term contracts with smallholder cooperatives or large buyers to ensure steady sales

Focus on consistent quality to build a reliable brand reputation in the local market