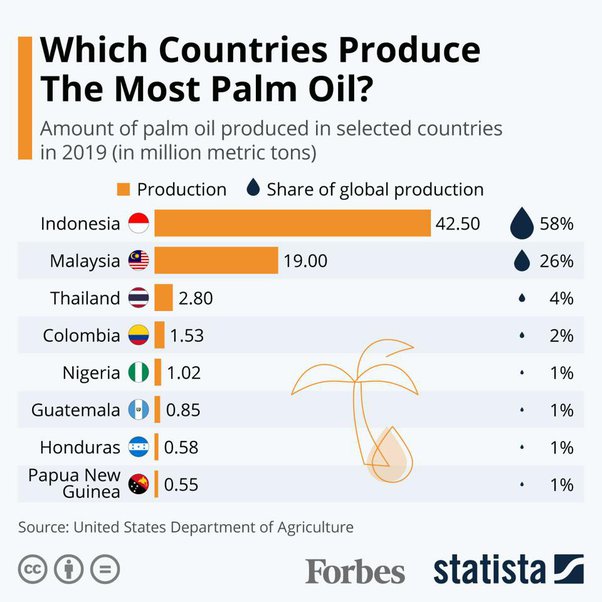

Indonesia is the largest palm oil producing country in the world. According to United States Department of Agriculture data in 2019 that around 58% of world’s palm oil comes from Indonesia.

Production of palm oil in Indonesia has recorded a phenomenal. Since 1964 to 2020, Indonesia managed to increase its production from 157,000 metric tons to 49,000,000 metric tons.

Palm oil production is important to the economy of Indonesia, accounts for 11% of Indonesia’s export earnings of $18bn per year.

Despite being opposed by many countries, mainly the European Union, palm oil has lifted millions of Indonesians (also Malaysians) out of poverty. Palm oil plantations have created millions of well-paying jobs, and enabled tens of thousands of smallholder farmers to own their own land. In Indonesia, the palm oil industry accounts for 1.6% of GDP and employs around 16 million people.

Palm oil is the most consumed edible oil worldwide. It is especially in high demand in West Africa, where it is used in almost every home for cooking and few other purposes. Presently, the global Palm Oil market is worth hundreds of millions of dollars. There are so many opportunities in Palm oil production for interested entrepreneur’s. You can make a lot of money by tapping into the lucrative market that this business has to offer, And guess what, the market is still vastly unsaturated, as evident in the fact that World Palm Oil producers such as Indonesia and Malaysia are still currently exporting to West Africa, Meaning that we are yet to fill the market

Asides from using it for cooking, palm oil is useful in the production of soap cosmetics, biofuels, coating of iron plates etc.

1. A well-situated space

It’s a no-brainer that the very first requirement is a suitable space to set up the plant. This is where all the activities of the business will be taking place. However, some

factors must be considered before choosing a location: the space should be close to the oil palm plantation, easily accessible with good terrain, and enough space for trucks that will convey the product.

2. Adequate and regular water supply

The milling process requires large volumes of water, whether for washing the fruits and equipment or cooking them. Instead of depending on public water supply or buying water, the best option is to sink a borehole within the premises to ensure adequate water supply.

3. Good quality equipment

If you want to optimize palm oil production in your mill, then you need the help of machines. The machines you need are those used for threshing, boiling, pressing andclarification. Depending on manual labour will lead to inefficient and minimal output with the tendency of wastage. The production output will depend on the size of the mill. Smaller mills will yield 1 tonne of palm oil a day whereas medium-sized or large ones can produce up to 10-100 tonnes per day.

For ease and smoother running of your business, you need to purchase the following equipment;

●Boiler

●Palm fruit stripper

●Nut fiber separator

●Pounding machine

●Mechanical screw press

●Barrels/surface tanks

4. Skilled workforce

Again, the size of your mill will determine how many hands you will hire. That means the bigger the mill, the more skilled workers and labourers you need. You will need the services of manual labourers in moving palm fruit from one location of the mill to another and unto the machine. It is important to hire trained staff or to train unskilled ones.

You will also need to hire a mechanical engineer who will see to the maintenance of the machines to ensure optimal operations. A quality control staff from the chemical science profession should also be on the ground to determine a standard quality palm oil.

The cost of starting a small-scale palm oil processing business is relatively modest. As long as you have enough money to start the business on your own, that’s fine; if not, other capital firms or banks may be able to help you out. For example, if you require funds to purchase machinery or to set up a business investment in an edible oil production plant, the bank will provide you with funds based on your specific demands. Here are some expenses you might need to be aware of before you start your palm oil extraction business plant.(Read More: How to Establish a Palm Oil Mill Plant in Nigeria)

1. Cost of Necessary and Reliable Palm Oil Equipment

The kneading and pressing procedures were used to obtain palm oil in the past. However, it results in a huge amount of palm oil wasted after using this procedure. Today, advanced palm oil processing plants can extract the majority of the oil from the palm fruit. Furthermore, most palm oil production processing and manufacturing can be installed locally, cutting costs and enhancing efficiency for palm oil producers.

2. Cost of Setting Up a Palm Oil Mill

Professionals may be required to set up the infrastructure and put it in processing devices. In most cases, the palm oil processing machine supplier or manufacturer will have engineers on hand to help you design the plant layout, install and commission the equipment.

3. Cost of Hiring and Training Workers

The palm oil production plant should have professional workers who can be hired or specially trained to operate all the equipment. For large palm oil processing plants, additional personnel may be required, such as security personnel, administrative staff, and so on.

1. Palm fruit/bunch → sterilization → threshing → digesting → pressing→ clarification → purification →dring → CPO→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

2. Palm kernel →depericarper → crushing → pressing → CPKO → refining → RBDPK oil, RBDPK olein & RBDPK stearin

Fresh Palm Fruit Reception: It is used for temporary storage and unloading fresh palm fruit bunches from palm plantation.

Palm Bunch Sterilization with the aid of steam: this loosens the oil-containing fruit from the bunch and inactivates lipid-degrading enzymes as well as micro-organisms that naturally occur in FFB.

Palm Fruit Threshing, bunch stripping which separates the fruit from the bunch stalk and spikelets. In this process, the byproduct Empty Fruit Bunch (EFB) is produced..

Palm Fruit Digestion to crush and disrupt the mesocarp (pulp), with the aid of steam.

Palm Fruit Oil Pressing of the digested fruit to extract the oil from the mesocarp fibre. In this process, two fractions are produced: raw oil and a residue, containing palm oil fibres and nuts.

Clarification and drying: The crude palm oil is separated from the mixture of oil, water and solid impurities by clarifying equipment, and other impurities are removed.

Crude Palm Oil Refining: The deacidified palm oil is refined, including bleaching, deodorization, dehydration and other processes to further improve the quality of the palm oil.

Palm oil comes from the fruit of the oil palm tree. 85% of the world’s supply is from Southeast Asia. The fruit of this tree grows in heavy bundles at the top center of the tree and is harvested by hand. The large bundles are cut using poles and the heavy bundles of hard fruit fall to the ground where they are gathered and taken to palm oil “factories”. In a few years, the trees reach heights of 40 feet or so, making harvesting by hand impractical. The trees are killed, removed and new ones planted.

The fruit bundles are then cooked with high pressure steam to soften the fruit, sterilize it, stop enzyme activity and burst the small oil sacks inside the fruit. The fruit is physically separated from the stalk (spiral conveyor blades and screens) and they are pressed to release the oil from the pulp.

The nut is further processed to separate the shells from the kernels which are prized for their oil which is has a much higher saturated fat content and lighter color.

All pulp, stalk material and shells are used for heat generation needed in the process.

The oil is refined by centrifuges and filtration, leaving a clear but dark oil from the fruit (due to carotenes) and a lighter colored oil from the kernels. The oils are separated into other products by fractionation, crystallization and bleaching to produce solid and liquid products. The “refined, bleached and deodorized palm oil” (RBDPO) is the primary product used in food production around the world based on its quality and low price compared with other oils.

A complete palm oil processing mill plant with a capacity of 50 ton/day is about $ 60,0000, while a full complete palm kernel oil production line with capacity of 10 ton/day is $ 60,000 around. It is the raw material for palm oil mills. The oil palm tree (Elaeis guineensis) originates from West Africa and was developed into an agricultural crop in Malaysa. The fruit from the tree is processed and has two main products crude palm oil and palm kernel.