Palm oil in Nigeria is used mainly for cooking and frying as it is rich in carotenes (vitamin A precursors) tocopherols and antioxidants, hence the interest in its use in Africa as a natural source of vitamin A. Oil palm plantations or estates cover around 118 264 ha but make up only 5% of the total crude palm oil production in Nigeria.

If you are planning to invest in a palm oil mill plant factory and have limited budget, some machines that can be replaced to save equipment cost. For detailed PKO mill plant solution, you are welcome to contact us and tell us your needs. Our professional engineer team will help you make the best palm oil mill plant solution and also offer the best price.We are committed to providing cost effective machinery and equipment which conform to the international quality standards, provides turnkey palm oil mill plant project including process design, palm oil mill machine manufacturing, installation, commissioning and training services. So far, QIE Machinery has successfully installed many palm oil mill plant projects in Nigeria. (Related Posts: Modern Palm Oil Production Plant: Full Automation & Low Cost>>)

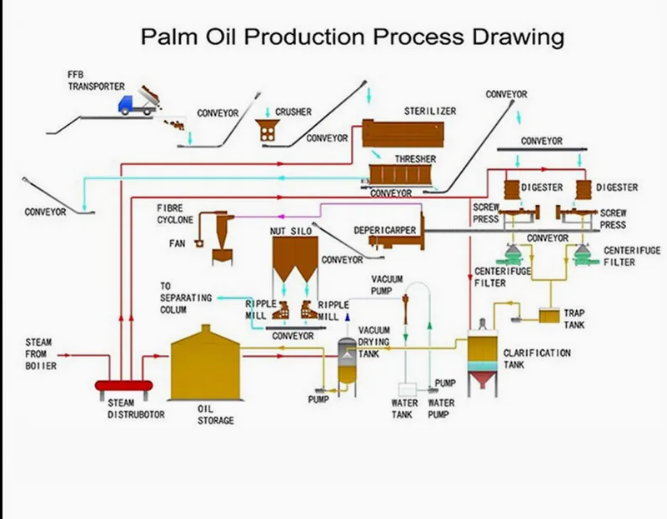

Palm oil mill plant refers to the palm oil production process to extract crude palm oil out from fresh palm fruit bunches(FFB). The standard palm oil production process mainly includes seven steps.

(1)Raw materials reception: Collect the FFB and convey them by trucks, then pour the fluster into the discharge door after weighed. Open the gate of the discharge door, then the palm fruits will fall into the FFB conveyor.

(2)Sterilizing: Boil the palm fruit for about 60mins by injecting 0.3MPa direct steam into the sterilizer. The purpose is to break the enzymes in fruit and to avoid the increasing of the FFA content in oil. At the same time, the high temperature makes the fruits soften, it’s easy for fruit threshing.

(3)Threshing: Adopts drum type thresher to separate the palm fruit from FFB. On one hand, it prevents the empty palm fruit bunch from adsorbing oil to reduce the palm oil yield and wearing equipment; on the other hand, the empty palm fruit bunch can be recycled.

(4)Digesting: Use high temperature to soften the palm fruit and crush the palm fruit so that the pulp and nut can be separated and the palm oil yield can be increased.

(5)Pressing: Adopt palm oil expeller to press the palm fruit pulp and extract the palm oil out.

(6)Clarification: Use the palm oil clarification machine to filter&purify obtained palm oil and remove the impurities in it to obtain crude palm oil.

(7)Mixture of fiber and nut recovery: The mixture of fiber and nut can not only be used as fuel and fertilizer, but also can be used to extract palm kernel oil.

The machines used in the palm oil pressing line includes steriliizer, thresher, digester, palm oil expeller, vibrating screen, plate filter, etc.

Related Post: Palm Oil Mil Plant Setup Costs in Nigeria>>

Palm oil refinery is an essential process for a complete palm oil mill plant because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude palm oil. QIE Machinery, as a professional palm oil refinery manufacturer who is devoted to processing pure edible oil for worldwide customers. We can provide professional technical support and first class palm oil refinery plant and other palm oil machine for customers.

Neutralizing Section

First stage of crude palm oil refining process is to remove Free Fatty Acids (F.F.A.) with caustic soda treatment called Neutralizing Process, thereafter further processed in the bleaching section under vacuum & treated with bleaching earth & activated carbon for removing colour. Finally it will be deodorized under high vacuum and high temperature to remove the odour from the oil.

Bleaching Section

The Oil received from previous stages contains traces of soap, iron and few ppm of Phospholipids and Carotenes. These contents are undesirable and required to be removed in Bleaching Operation of crude palm oil refining process, Doing’s Steam Agitated Bleacher comprises of an acid treatment, a separate Oil and Earth Mixing Device with Mechanical Mixer (this arrangement ensures no carryover of bleaching earth into vacuum system), main bleaching vessel and Hermetic Filters.

Deodorizing Section

Physical Refining process is used to remove FFA (Free Fatty Acid), using Steam Distillation method at high temperature and under high vacuum and it is followed by Deodorization and an extra technical facility is added before deodorisation for removal of free fatty acid.

Deodorization process is used to remove unacceptable odour by Steam Distillation, the Odoriferous Compound are strip off with the help of live injected steam into heated oil under high vacuum.

Investment in palm oil mill plants in nigeria has a stable and broad market development prospects, mainly reflected in the palm oil processing raw materials sufficient, large market demand, and large profit margins.

Palm fruit raw materials are sufficient

The palm fruit tree is a long-term crop with four flowering and fruiting seasons. It can provide a stable and continuous supply of raw materials for palm fruit processing, and the yield per hectare of palm fruit is 5 times higher than that of peanuts in the same area, and 9 times higher than that of soybeans. People who have seen oil palm trees know that the fruit of oil palm trees is very rich, a large string, the fruit is orange red when ripe, and the average weight of each string can reach more than 100 pounds. In addition, the growth cycle of oil palm trees is perennial, blooming and bearing fruit all year round, and can harvest several times a year. And not only the fruit, the peel can also be used to press oil, so the oil yield per unit area of palm oil is also quite high. It requires very little to grow an oil palm tree, a tropical fruit tree that can survive in Asia, the Americas, and Africa. As long as the external environment meets its growth, it will seize resources and strive to grow at all costs.

Palm oil market demand is large

At present, the palm oil imported from China is mainly used in the processing of composite edible oil, because of its low boiling point, many are used in the processing of instant noodles and biscuits. Palm oil also has many uses in the catering, food industry and oil and grease chemical industry. Palm oil is currently the world’s largest vegetable oil production, consumption and international trade volume, accounting for 30% of the world’s total oil consumption. This means that the market demand for palm oil is very high.

Palm oil has large profit margins

The net profit and rate of return on the production investment of palm oil mill plants are often the focus of our attention and one of the main criteria to measure the development prospects of palm oil mill plant projects. The net profit margin of palm oil is about 5% higher than that of soybean oil and peanut oil.

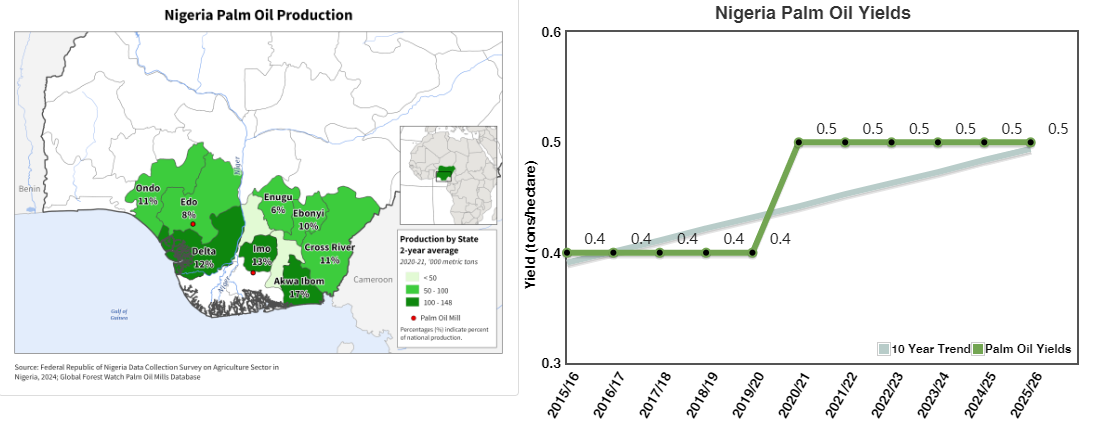

In the last five years (2014 – 2018), Nigeria consumed 6.6 million MT of CPO. Out of the total consumption, local production represented 75% or 4.93 million MT thereby causing reliance on importation for the shortfall of 25% or 1.67 million MT.

According to Vegetable and Edible Oil Producers of Nigeria (VEOPAN), palm oil production provides jobs for at least 1.8million Nigerians. Because the local production is not up to demand, Nigeria at present does not export palm oil. The local shortfall is being supplemented by imports from countries such as Malaysia and Indonesia.

In 2023, Nigeria’s palm oil production reached 1.4 million metric tons, marking a steady increase since 2009, with significant growth observed in 2010. According to Statista, Nigeria now ranks among the top five global producers of palm oil.

Despite this, Nigeria’s annual consumption for oil palm produce lies at 2.4 million tons, with local production meeting only 50% of demand leaving FMCGs like Indomie still having to import Oil palm because local demand outstrips supply. Nigeria now produces a meager 1.7 percent of total world production which is inadequate for local consumption put at about 2.7 percent.