Palm oil mill plant production line is a multi-stage process involving specialized equipment and techniques to convert fresh palm fruit into refined edible palm oil. The palm oil processing plant capacities range from 3tph to 120tph. Our unique patented palm oil equipment and techniques are highly efficient in handling the specific properties of palm fruits and achieving maximum oil yield and quality. We have the best solutions for you in each stage, from palm sterilization and threshing to palm oil extraction and refining.

Brand

QIE

Raw Material

Palm Fruit, Palm Kernel

Capacity

3-120TPH

3-120TPH

Customized Palm Oil Mill Plant Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

Palm oil processing equipment, from the initial fresh bunches to the final palm oil, requires professional technology to achieve the best possible oil yield and higher quality oil for more efficient production. Based on the growth characteristics of processing capacity of the customer, and taking into account the return on investment, QIE Machinery have designed two main types of palm oil production lines and below shows list of palm oil processing equipment.

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market. We offer you complete palm oil pressing refining plant solutions, from plant layout design to palm oil equipment manufacturing, debugging, and installation.

CPO(crude palm oil)→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin

The degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Alkali solution (typically sodium hydroxide) is added to neutralize free fatty acids. Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil. We can add some lye to neutralize the free fatty acid, this process is also called alkali refining.

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. All the pigments can be removed by the adsorbents method. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Palm oil is by far the most important fractionated oil in the world; crude, semi- and fully refined palm oil can be fractionated in multi-stage, giving access to several products for specific applications. The typical fractionation process of palm oil mill is pre-heating, cooling, crystallization, and filtering.palm oil fractionation plant adopts advanced crystallization equipment, filtration equipment, and accurate temperature auto-control software to separate palm olein and palm stearin which can get different melting-point fractionation products, including 18℃, 24℃, 32℃, etc.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

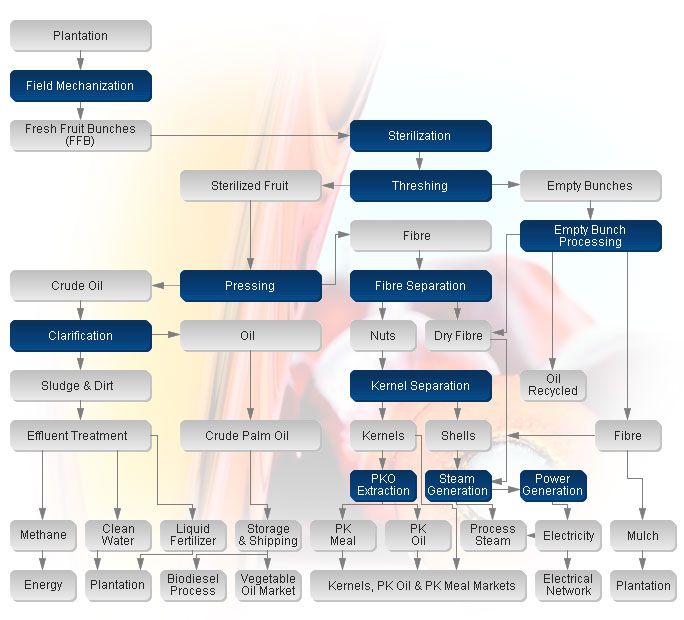

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

Learn MoreEffluent from hydration and degumming stage of refining process. The crude phospholipids separated from the palm oil refining section contain a large amount of water, which needs to be dehydrated by the concentrator, and after concentration, the evaporated water is condensed and discharged as effluent.

Indonesia is the largest producer of palm oil in the world, contributing over 46 million tonnes annually. Learn why Indonesia leads global palm oil production, key producing regions, and major export markets.

Biomass from palm fibers and shells is often used as boiler fuel.

Biogas from effluent treatment, which powers generators.

Electricity from the grid or mill-generated power for automated systems.

The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

The three main by-products from the process of extracting oil from palm kernels are the Empty Fruit Bunches (EFB), the Palm Kernel Shell (PKS), and the Mesocarp Fibre (MF).

Crude palm oil (CPO) is raw oil extracted directly from the fruit, containing impurities. Refined palm oil undergoes further processing (degumming, deacidification, bleaching, deodorization) to produce a cleaner, lighter oil suitable for food and industrial applications.

Palm kernel oil extraction involves:

Crushing the palm kernels after the fruit pulp is processed.

Using a palm oil screw press machine or solvent extraction to obtain the oil.

Palm kernel oil is more saturated and harder than palm oil, making it suitable for soaps and non-food products.