As we all know, oil palm is an important oil crop since it has very high oil content. Both the palm fruit and palm kernel of the palm fruit can be extracted vegetable oil. The oil content of palm fruit is 46% ~ 50%, and that of palm kernel is 50% – 55%. Palm oil and palm kernel oil are the commonly used cooking oil in Nigeria, Malaysia, Indonesia, Liberia and Congo.

Nigeria holds a prominent position in the global palm oil market, being one of the largest producers worldwide. In recent years, the country’s palm oil production growth has largely stagnated while local demand has been increasing, creating an profitable investment opportunity in the form of a huge supply-demand gap.

Oil refining is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude palm oil, getting standard palm oil.So palm oil refining machine is the major equipment to refine crude palm oil.

Palm oil refinery plant is a way to get rid of the harmful impurities and needless substance in the crude oil, aims at improving the oil storage stability,flavor and color.then get standard edible oil or provides qualified material for deep processing.Palm oil refinery process usually includes the following sections: degumming and deacidification, decolorization, and deodorization.(More about Ultimate Guide to Palm Oil Manufacturing Plant)

For most entrepreneurs who want to start palm oil refining business in Nigeria. The investment costs might be their top concern. To figure out the cost of the palm oil refinery investment, you must think about the followings 3 questions firstly:

What’s your raw materials? Fresh Palm Fruits, Palm Kernel or Crude Palm Oil? If you want to process fresh palm fruit bunches into refined oil, then you will need machines for palm oil extraction and refinery. If you have got crude palm oil and want to get Refined, Bleached and Deodorised (RBD) palm oil, then you just need to buy oil refining machines.

What’s the size of the refinery you want to build? Mini scale (1-5ton/d), small scale (5-10ton/day), medium scale (10-20ton/day) or large scale (more than 20ton/day)?

Is palm oil fractionation process needed?

The cost of a palm oil refinery with capacity around 1ton/day is about $20,000. For setting up a 5 ton/day small scale refinery, the cost could be around $40,000. If you plan to start an 50-100ton/day industrial scale palm oil business in Nigeria, the investment could be $170,000~$500,000. Besides, you should know that the cost is also greatly related with the palm oil refining process design. There are 3 common types of refining process for palm oil production: Batch Oil Refinery, Semi-Continuous and Continuous Oil Refinery.

Palm oil refinery is an essential process for a complete palm oil mill plant because there are still some impurities such as phospholipids, FFA, pigment, odor,etc. in the crude palm oil. QIE Machinery, as a professional palm oil refinery manufacturer who is devoted to processing pure edible oil for worldwide customers. We can provide professional technical support and first class palm oil refinery plant and other palm oil machine for customers.

In general, palm oil refinery plant devides to 3 types: batch palm oil refinery plant, semi-continuous palm oil refinery plant, continuous plam oil refinery plant. These 3 oil refinery plants are used for different capacity. But the processes in each oil refinery plant are almost the same.

1.Degumming.

In this step gums in crude oil are removed by hydration with the help of phosphoric acid. Degumming is the first step for the whole palm oil refinery process.

2.Neutralization

In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.Neutralization is also called deacidification, it is the important part for palm oil refinery.

3. Bleaching

During bleaching, unwanted pigments are adsorbed physically and oil will become much clearer. Bleaching is also decolorization in palm oil refinery.

4. Deodorization

Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high vacuum pressure. Deodorization is mainly for making oil color lighter during palm oil refinery process. Which can make oil looks good.

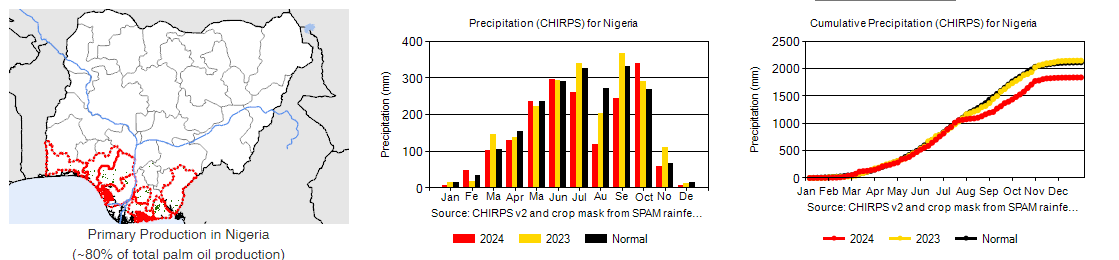

Amidst being the largest global Oil palm exporting country at the beginning of the 20th Century, Nigeria’s oil palm industry still faces many challenges that require urgent attention to achieve sustainable palm oil production to cater to and satisfy the local daily needs. Oil palm production is categorized into three groups; smallholders, medium, and large-scale plantations (Ayodele and Ehalomi, 2010). According to a case study by the Initiative for Public Policy Analysis (IPPA), the small holding control over 80% of Nigeria’s palm oil production. The government and a few private companies own fairly large plantations.

Nonetheless, the abundance of resources for palm oil production in Nigeria still is under critical condition due to the long-time palm oil industry producing and competing.