Processing Material: Palm fruit

Processing Capacity: 5-120TPH

The first process is the reception of FFB (Fresh Fruit Bunch) in Palm oil mill.

The FFB arrives in a mil in trucks or trailers. These are first weighed over a weighbridge. The trucks then go to the FFB loading ramp, where they are emptied. Most trucks have tipping containers and the trucks can be unloaded fast. In many remote areas the trucks are manually unloaded, and this takes time.

The FFB arriving at the mill has to be checked for quality. Ripe FFB yields very much more oil than under ripe FFB. The major factors that will determine the quantity of oil (Oil extraction Ratio- OER) is the ripeness of the FFB.

Weighing: All incoming truckloads are weighed using road weighbridges to record raw material tonnage for payment and yield tracking.

Quality Grading: Graders inspect bunches to categorize them by ripeness (unripe, under-ripe, ripe, or over-ripe) and damage. This assessment determines the Oil Extraction Ratio (OER) and any price deductions for poor quality.

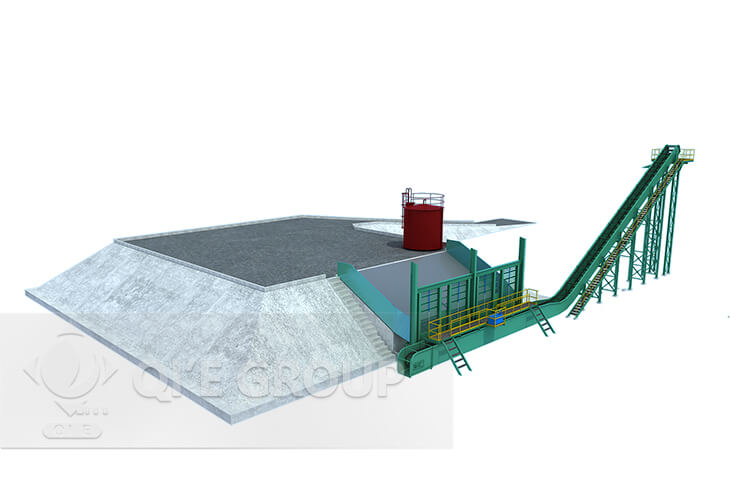

Logistics & Loading: FFBs are unloaded into loading ramps or storage hoppers. In modern mills, these ramps use hydraulic segmented discharge to transfer fruits into conveyors or sterilizer cages.

Equipment List of Reception Station

1.Road Weighbridge

2.FFB Loading Ramp C/W Platform&Hydraulic System

3.FFB Scraper Conveyor No.1

4.FFB Incline Scraper Conveyor No.2

5.FFB Distributing Scraper Conveyor

6.Recycling FFB Conveyor

Effect Factors of Final Palm Oil Quality and Composition

Oil Palm Tree Species

Oil Palm Tree Age

Agronomic

Natural

Gathering Technique

Handling And Transport

Why is the 24–48 hour rule so strict?

After harvest, enzymes in the fruit quickly break down oil into Free Fatty Acids (FFA), especially if the fruit is bruised. Processing within 24–48 hours is critical to keeping FFA levels low (ideally below 5%) and maintaining a high commercial value for the oil.

What are the primary criteria for “Ripe” bunches?

According to standard grading guidelines, a Ripe Bunch is typically reddish-orange and should have at least 10 loose fruitlets already detached. Ripe fruit contains the maximum amount of extractable oil.

What reasons can lead to a batch being rejected or penalized?

Mills may apply price deductions or reject batches for the following reasons:

Under-ripe/Unripe: Hard fruit with low oil content.

Long Stalks: Stalks longer than 5cm absorb oil and increase transport costs.

Dirty Bunches: Bunches mixed with more than 50% mud, sand, or stones.

Pest Damage: More than 30% of the bunch damaged by rats or other animals.

How does the mill handle “Loose Fruit”?

Loose fruits (detached fruitlets) actually have the highest oil content. They must be collected and received alongside the bunches, as they are often used to help determine the overall ripeness of the delivery.

What equipment is essential at the reception station?

Road Weighbridge: To log the exact tonnage of raw materials for payment.

Loading Ramp: A platform for unloading trucks and providing temporary storage before sterilization.

Hydraulic Gates: Used to control the flow of fruit from the ramp into conveyors or sterilizer cages.