Palm oil is a kind of tropical woody vegetable oil, which is the largest variety of vegetable oil produced, consumed and internationally traded in the world at present. With soybean oil and rapeseed oil, it is also known as “the three major vegetable oils in the world”. It has a edible history of more than 5,000 years.

The fresh palm fruit string is 100% of the total palm fruit string, the proportion of empty fruit string is 23%, the palm fruit is 65%), and the palm oil content of the whole palm fruit string is (26%), and the palm kernel oil content is 3.25%.

Nigeria is a major global palm oil producer, primarily driven by smallholder farmers in southern states like Akwa Ibom, Edo, and Ondo, but faces a significant supply-demand gap despite its rich history as a leading producer before crude oil’s dominance. Production involves traditional methods like boiling and pounding or modern presses, yielding valuable red oil for food and byproducts for cosmetics, though industry growth struggles with infrastructure and meeting soaring local demand, creating import reliance.

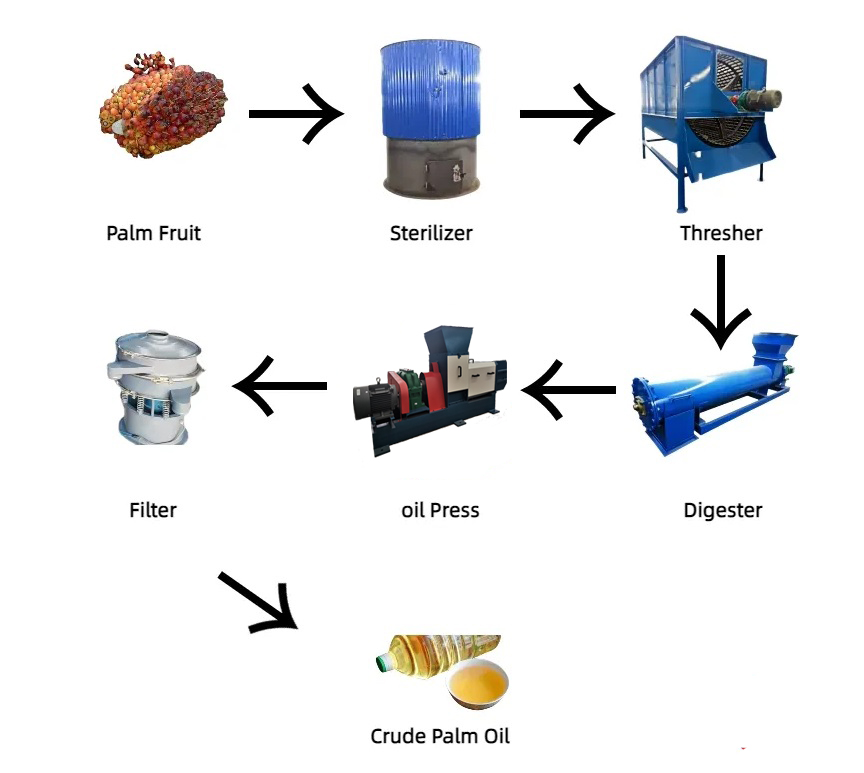

The 1-5tph palm oil production line is mature in technology, simple in structure and easy to operate. Mainly include:sterilizer, fruit stripping machine,digester pot, screw press, crude oil cleaning and nut & kernel recovery,etc.

Our CPO technology & equipment, more sets are sold and installed in Africa, South-East Asia, with high yield, low investment,advanced technology.

Raw material reception section –Sterilization station–Threshing section –Dighesting&pressing station –Oil clarification station–Kernel recovery station

Reception station:

The palm oil processing plant starts after the harvesting of the palm fruit bunches where they are taken to the palm oil mill for processing. During the harvesting process the fruits should be handled with care to prevent bruising them as the bruise reduces the quality of oil extracted.

Sterilization Station:

Sterilization process follows where a lot of heat is used to cook the fruit. In this station of palm oil processing, enzymatic reactions are also stopped, arresting hydrolysis,auto-oxidation and the outer cover of the fruit (exocarp) is also weakened allowing easier oil extraction from the fruit. This process can be done by either roasting/smoking which is done after threshing process or by steaming/boiling which should be done before threshing process.

Threshing Station:

The fruit bunches then undergo threshing which separates the fruitlets from the bunch in a rotating drum. It can be done manually or a mechanical by use of palm oil processing machinery – thresher / threshing machine. The loose fruits are then conveyed to the another palm oil processing machine – digester, and the empty fruit bunches are separated and returned to the plantation or used as fuel in the boiler.

Digesting Station:

The fruits are then digested in the digester. This process involves the crushing of the fruits and warming the pulp before oil extraction is done. Warming is important in order to maximize oil extraction.

Twin Screw Palm Fruit Oil Press Machine:

Oil is then clarified, in this process impurities screening is done whereby large solids of fiber and dirt are removed from the raw oil .Water is then added to the raw oil in order to improve the separation process. After sieving process the raw crude oil is obtained but it still contains fine solids and water. Water is removed by introduction of a steam in the coils (increasing the temperature in the coils). The fine solids that are in the oil are removed finally as they sediment hence separating oil from the sludge to obtain about 163 kg of oil per one tone of the palm fruits processed.

Kernel recovery station : The pressed cake (fiber&nut) is transported to the fiber separation system for fiber&nut separating ,the separated nut is sent to nut silo for temporary storage .

| Process Step | Key Equipment | Function |

|---|---|---|

| FFB Reception | Weighing scale, Hopper | Receive and weigh FFB; buffer for steady feeding |

| Sterilization | Vertical/horizontal sterilizer | Inactivate lipases, soften fruit, prevent oil rancidity (100°C, 1–2 hours) |

| Threshing | Drum thresher | Separate palm fruits from bunches |

| Digestion | Steam-heated digester | Mash fruits into pulp for better oil release |

| Pressing | Screw press (YZYZ series) | Extract CPO from pulp; capacities: 1tph (5.5kW), 3tph (11kW), 5tph (15kW) |

| Clarification | Decanter centrifuge/plate filter | Remove impurities, moisture, and solids from CPO |

| By-product Handling | Fiber separator, nut cracker | Recover palm kernel (for kernel oil) and fiber (fuel/biomass) |

Q: How much space is needed?

A: 3–10 m³ for equipment; add storage for FFB, CPO, and by-products (palm kernel, fiber).

Q: What is the expected CPO yield and quality?

A: Yield: 18–22% of FFB (varies with FFB maturity, moisture, and process efficiency).

Quality: CPO with FFA ≤5%, moisture ≤0.1%, impurities ≤0.2%, and color R 3.0–5.0/Y 30–50 (AOCS).

Optimization: Maintain FFB moisture 10–12%, digestion temp 75–85°C, and pressing pressure 30–40 bar.

Q: What regulatory and compliance steps are needed in Nigeria?

A: Licenses: Obtain NAFDAC registration for edible oil, SON certification for equipment, and local government permits (LGA).

Standards: Comply with SONCAP (imported equipment), NIS 66:2009 (CPO quality), and environmental regulations (wastewater discharge ≤50 mg/L BOD).

Taxes: Register with FIRS for VAT (7.5%) and corporate income tax (30%); apply for agricultural incentives ( Pioneer Status for 3–5 years).

Q: How to source FFB and manage the supply chain?

A: Sourcing: Partner with smallholder farmers (5–10 km radius) for consistent FFB supply; offer fair prices (₦150–200/kg) and timely payments.

Storage: Use shaded, well-ventilated facilities; avoid stacking >2 m high to prevent heating.

Transport: Use covered trucks to avoid rain damage; maintain cold chain (if needed) for long distances.