Palm oil comes from oil palm trees, or Elaeis guineensis. While palm kernel oil is extruded from the palm seed, palm oil comes from the palm fruit. Relative to palm kernel oil and even coconut oil, palm oil has a lower ratio of saturated fat. Trans fats have got a bad rep in the past few years, and palm oil has offered itself as a better alternative; according to health experts from Harvard, it may even be a better option compared to butter. Not only is it healthier than animal fats, but it is also cheaper and easier to process.

Where exactly is palm oil used? It may be easier to answer where it is not. Everything from the oil you use to cook to the skincare products you apply on your face, from pizza dough, instant noodles and chips, to soap, shampoo, animal feed and biofuels all use palm oil or by-products of its extraction, refining or related processes. Given its utility across so many industries, it is not surprising that palm oil has witnessed increasing demand in the past few years.

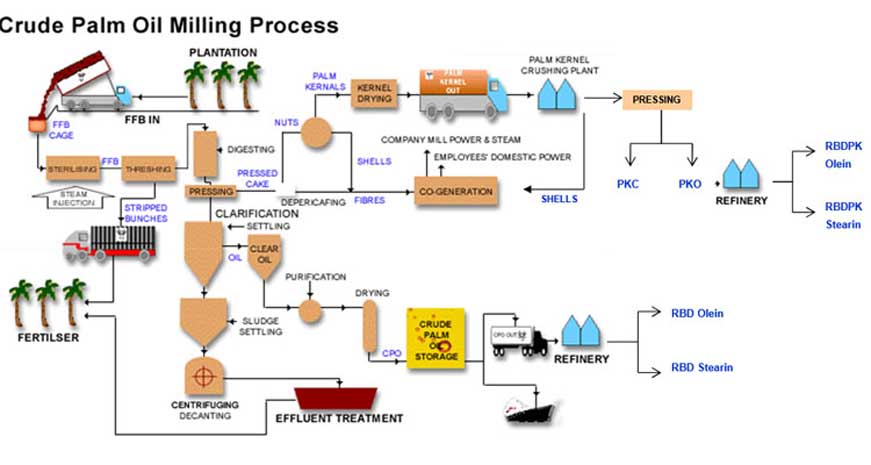

The complete palm oil production process consists of three main parts: palm oil pressing, refining and fractionation.

Oil palm fruit bunches → Sterilizing → Threshing → Digesting → Screw/Hydraulic pressing → Filtration → Crude palm oil

Sterilizing Process: Fresh palm fruit bunches received from the plantations are steam-fermented at high temperatures to destroy the lipase enzyme in the pulp to facilitate fruit removal.

Threshing Process: Palm fruits are separated from the bunches using a thresher. There are two common types of threshers: simple type threshing machine and drum type threshing machine. Manual de-fruiting is also an option.

Digesting Process: The palm fruits are mashed into a paste. The mashing process destroys the cellular structure of the palm fruits and improves the efficiency of palm oil extraction.

Pressing Process: Pressing is a key part of palm oil making. This step requires strict temperature and pressure control. As a palm oil production equipment manufacturer, QIE Machinery can provide you with single screw palm oil press machine and double screw palm oil press machine.

Clarification Process: Crude palm oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge will be taken out.

Crude palm oil → Degumming → Deacidification → Decolorization → Deodorization → Refined palm oil

Degumming Process: removing some of the waxes, impurities, and pigments that may be present in gross palm oil. This step usually involves freezing or heating to solidify or dissolve the impurities, which are then separated by methods such as filtration or centrifugation.

Deacidification Process: Reducing the free fatty acid content of palm oil. This is usually done by alkaline treatment or steam deacidification.

Decolorization Process: Decolorization is the process of removing the pigments from hairy palm oil to make it more transparent in color. This step usually involves activated clay or other adsorption to adsorb the pigment particles.

Deodorization Process: Removal of off-flavors and undesirable odors from the oil by steam deodorization or other techniques helps to enhance the flavor of palm oil.

Refinery machines play a pivotal role in the palm oil industry, contributing to the production of high-quality palm oil that meets stringent standards for both domestic and international markets. These machines are essential for the transformation of crude palm oil (CPO) into refined, bleached, and deodorized (RBD) palm oil, which is suitable for a wide range of applications. Hence, here is a table showing machinery used to refine palm oil:

| Name of Machine | Description/Features |

|---|---|

| Neutralizer | A neutralizer works to reduce the free fatty acid (FFA) content in crude palm oil (CPO), improving its quality for various applications. This is achieved through a chemical reaction with an alkaline solution. |

| Bleacher | The bleacher’s role is to remove pigments, impurities, and residual free fatty acids from CPO. It employs adsorbents, like activated clay, to enhance the clarity and appearance of the oil. |

| Deodorizer | The deodorizer is essential for eliminating undesirable odors, off-flavors, and volatile compounds present in CPO. It operates under vacuum conditions to ensure odor removal while preserving oil quality. |

| Clarifier | A clarifier machine separates impurities from oil using gravity settling, contributing to oil purity and clarity. |

| Filtration System | The filtration system removes fine particles and solids from the oil, ensuring it meets quality standards. |

| Heat Exchanger | It helps maintain temperature control during the refining process, ensuring consistent and efficient operation. |

| Deaerator | Removes dissolved gases from the oil, improving stability and shelf life. |

| Steam Generator | A steam generator works as a steaming machine for various refining processes. |

Refined Palm Oil → Heating Section → Crystallization Section → Filtration Section → Palm Soft Fat + Palm Stearin

After refining palm oil, crystals will precipitate at low temperatures, so fractionation may be an option for the stability of the oil in storage or for different applications.

Professional customization: Our professional team will develop a personalized palm oil processing solution according to your needs, to ensure maximum satisfaction of your production requirements.

Factory Layout Design: QIE Machinery pays attention to every detail to create an optimal factory layout for you, which will improve production efficiency and reduce resource waste.

Advanced Technology: We always pay attention to the latest technology trends in the industry and adopt advanced equipment and processes to ensure that your palm oil production is at the forefront of the industry.

One-stop service: QIE Machinery simplifies the whole process into a one-stop service, you just need to focus on your business and leave the rest to us.