Small scale palm oil mill plant generally refers to the palm oil processing production with the capacity 10-50 ton per day. We have two small palm fruit processing solutions for your! One is small scale palm oil mill plant for 10~30 ton/day factory, and the other one is 30~50 ton/day palm oil milling plant for medium-sized factory.

If you want to produce palm oil automatically, 1-5tph small scale palm oil processing plant can fulfill your requirement. It is a whole line machine from FFB to red palm oil. And the machines used in the small scale palm oil processing plant are all designed specifically for the small scale plant by QIE Machinery, which have palm fruit sterilizer, palm fruit thresher, palm fruit digester, double screw palm oil presser machine, crude palm oil clarification machine, red palm oil filter machine, crude red oil tank and so on. (Read more: How to Start a Successful Palm Oil Production Business in Nigeria >>)

Raw material : FFB (fresh palm fruit bunch ) ,Output :CPO(red palm oil)

The main process :

FFB(fresh palm fruit bunches)—Reception— Sterilizing —Threshing —Crushing—Pressing—Oil clarification —CPO(crude palm oil)

The main machine in the production line :

1.Sterilizatuib station : The purpose of sterilizer is used to break the enzymes in fruit ,and avoid the increasing of the FFA content in palm oil . at the same time ,The high temprature makes the fruit soften ,it is easy for fruti threshing

2. Thresher station : The purpose of sterilizer is to separate the palm fruit from the FFB . we mainly adopts drum trype thresher . there is a rotarty drum inside of the threshing mahcine ,the separated palm fruit is sent to the pressing station . empty palm fruit bunches are discharged from the other side of the thresher .

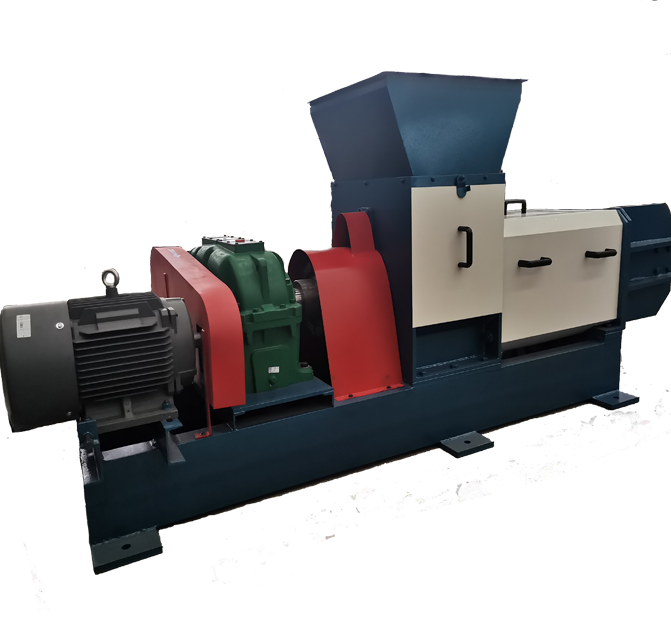

3.Digesting &pressing station : Digesting is for crushing palm fruit ,Use high temperature to soften the fruit ,and crush pam fruit , It help to press oil out easily . Presing machine is used to press crude palm oil from processed palm fruit

4.Oil clarification station : It is used to filter impurities in the crude palm oil . The purified palm oil can be directly sold or deeply refined .

Now that you have arranged for the necessary equipment and goods it’s time to understand the process of palm oil extraction, refining and how to do the whole process.

Setting up the small scale palm oil plant is the great resource for your income. Since palm oil has great demand you can earn the pretty good profit in your local or small markets nearby. Palm oil is widely used in pharmaceutical, cosmetics industry, food products, and many such other industries. So, go for this if you want to set up something of your own and something that will never go out of demand.