Reception

To avoid excessive production of free fatty acids resulting from a natural enzymatic process in the mesocarp, it is recommended to limit transportation of fresh fruit bunches (FFB) from harvesting to sterilization to 72 hours. This is because fresh palm oil normally contains about 1% free fatty acids (FFA), which may rapidly increase with fruit maturation, decreasing the oil’s value.

Sterilisation

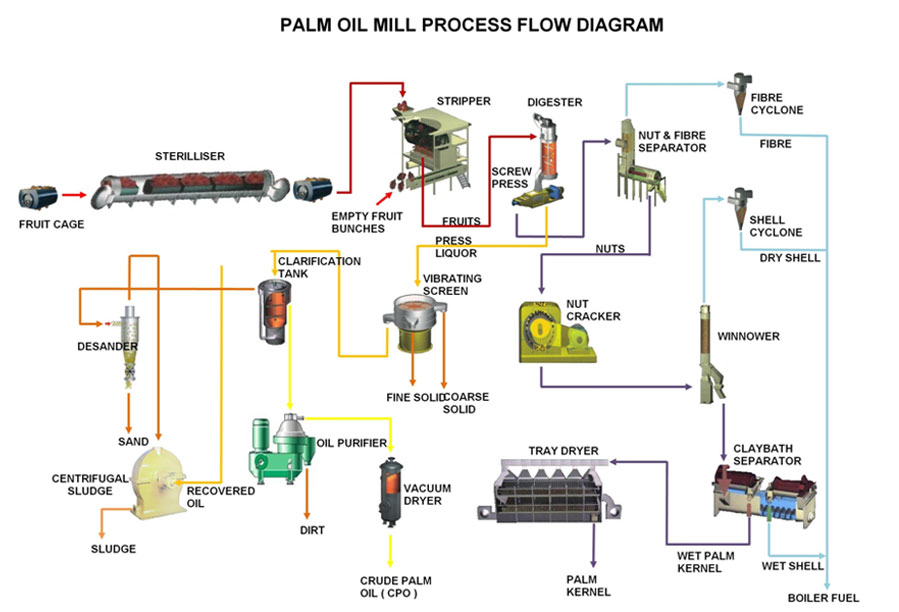

To prepare the FFB for oil extraction, operators use steam to sterilize them in autoclaves with a capacity of 20 to 30 tons, which helps inactivate natural enzymatic activity, loosen the fruit, and soften the mesocarp. The steam is applied at a temperature of 130°Celsius and a pressure of 3.1 bars for 90 minutes, ensuring the FFB are properly sterilized.

Threshing / Stripping

After sterilization, operators send the FFB to rotary drum threshers to separate the sterilized fruits from the bunch stalks. As a result of this process, residues such as empty fruit bunches (EFB) are generated, which typically contain moisture. Since it maintains soil moisture, EFB can serve as an organic fertilizer and soil conditioner. However, to achieve lower moisture content in the EFB, some mills employ EFB pressing techniques. This allows it to be used as biomass fuel in suitable boiler systems for steam/electricity production.

Digester & Pressing

The separated fruit is fed into a vertical steam-jacketed drum (cooker) for mechanical processing, converting it into a homogeneous oil slurry. Furthermore, to promote homogenization, hot water is added to the cooker before the oil slurry is fed into the oil press (screw press). The screw press then extracts palm oil from the oil slurry. After collecting the extracted oil phase, operators send it to a purification area. Simultaneously, they use physical methods to separate solid components such as fibers and kernels.

Clarification

To ensure the complete removal of all impurities from crude oil in palm oil production plants, a clarification process is required. This process involves transferring sludge to different tank chambers to remove particles and other suspended solids. Solids are primarily removed using gravity settling tanks, with centrifuges also used in other stages. Furthermore, the process includes introducing high-temperature water at 85-90 degrees Celsius to dissolve impurities. Finally, after clarification, the palm oil is dried using a vacuum dryer to evaporate the water content.

Oil Storage

Large palm oil mills typically transport refined and dried palm oil to storage tanks for shipment. To prevent palm oil from solidifying and fractionating, the temperature inside the storage tanks needs to be maintained at around 50°C, which can be regulated using hot water or low-pressure steam heating coils. Inadequate tank lining can lead to iron contamination. Therefore, temperature control of the storage tanks is crucial as it affects the oxidation rate of palm oil.

Nut & Kernel Separation

The screw press separates the solids from the oil slurry, followed by further physical separation of fibers and kernels. The separated fibers are used as biomass fuel for boilers, while the kernels are sent to a kernel crusher or corrugated mill section for palm kernel recovery. Palm kernels are another product of palm oil mills besides crude palm oil (CPO).

Palm Kernel Extraction

By ensuring efficient palm kernel recovery, the process prepares the palm oil pressing line for the next stage of pressing, following the splitting and crushing phases. Furthermore, efficient palm kernel recovery is crucial for producing high-quality palm kernel oil, which has a wide range of applications, including edible oils, food ingredients, and personal care products. Therefore, optimizing the palm kernel recovery process is essential for maximizing the output and profitability of palm oil mills.

Starting a Palm Oil Mill Plant in Malaysia

Feasibility Analysis

The Malaysia Palm Oil Processing Plant Business Feasibility Study looks at assessing the potential feasibility of establishing a palm oil milling plant in Malaysia. It provides investors with comprehensive information by examining the country’s abundant palm resources, demand trends in the palm oil market, and technological and environmental factors.

Site Selection

In the business of investing in palm oil processing mills in Malaysia, site selection is a crucial decision. Choosing the right location not only directly affects the factory construction process and the size of the investment, but also has a profound impact on the local economy, environment, agriculture and society. Factors such as climatic conditions, land availability and the surrounding environment are key to ensuring the long-term planning and sustainability of a palm oil mill.

Cost Analysis

Establishing a palm oil processing plant in Malaysia is a lucrative opportunity, and a careful understanding of the associated costs is key to success. Key steps include the cost of acquiring suitable land, infrastructure costs, processing machinery costs, and various management and operational costs.

Plant Layout and Design

Palm oil mill layout design is crucial, affecting production efficiency and operational safety. QIE Group has extensive experience in providing professional technical support to design the mill and equipment layout according to the actual situation. The design should follow the palm oil production process and ensure that machines is properly arranged to facilitate smooth production.

Equipment Selection

When setting up a palm oil processing plant in Malaysia, choosing the right processing machinery is critical, affecting productivity, cost, reliability and environmental sustainability. QIE Group can provide you with expert guidance in equipment selection, with our solutions focusing on meeting process requirements, prioritizing high efficiency and low energy consumption.

Environmental Impact

Investors in the palm oil industry are increasingly aware of the environmental impact of palm oil mill effluent (POME). By understanding the sources of POME, including its origins in the palm oil production process, investors can implement strategies to minimize the amount of wastewater generated and reduce environmental risks.